Process images

Week 05 refletions.

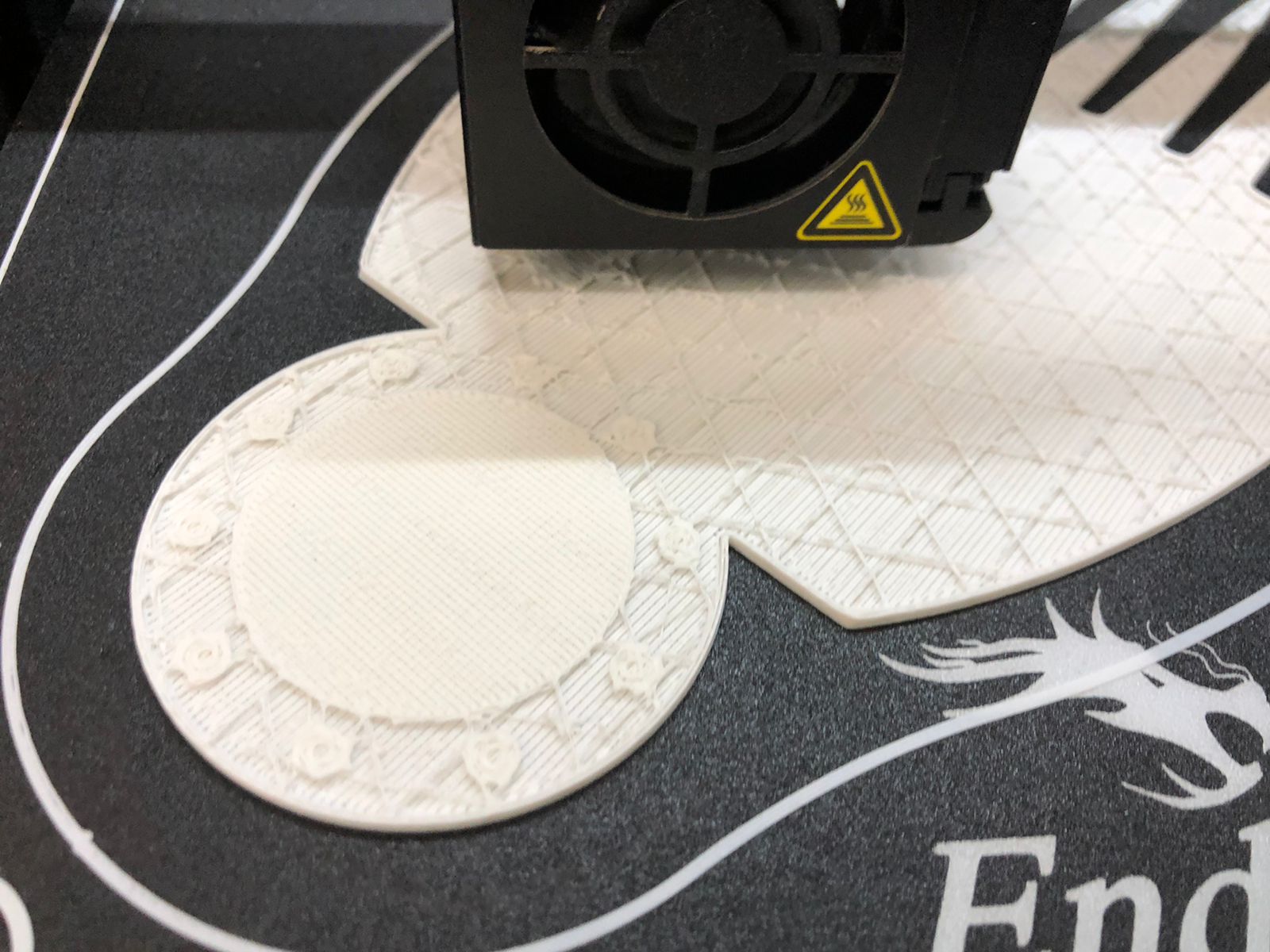

One of the things that surprised me the most this week was to notice that just 3d printing a piece was super easy but not that easy to have the perfect finishing. At first, I did a comb piece to make a mold for the biomaterial we had been developing at the same time. I had to print it twice to have an accurate finishing to reproduce later the piece without so much postproduction.

Later on, I did other pieces in 3d printing as a lamp diffuser profile. In this case, I had to choose between placing the profiles horizontal or vertical. Both options have good and bad things so it depends on the profile, the measures, and the finishing you want to have to make the choice..

Placing it horizontally gives you less time printing time but the worst finishing, also gives you the possibility to have longer profiles without cutting them. Placing it vertically gives you a good finishing of the profile but takes more time and you have to take care of the profile height because it can fall while printing because of the movement of the base.

During the weeks we learn how to fix a clogged nozzle and how to calibrate the base as a usual 3d print maintenance.

Finals reflections: I enjoy PLA 3d prints as a way of quick prototyping some ideas and having little joins because the properties of the material give you quite strong pieces. For artistic pieces that you need to have a polished finish, I think I prefer resin ones because give you this possibility. These machines are also “cheap” and easy machines to have at home and produce pieces with a very slow impact on material and energy use terms.